Pipe Manufacturing

◆Case Example

- 1. Micropipe

- 2. Resin tube tip forming die

- 3. Sleeves

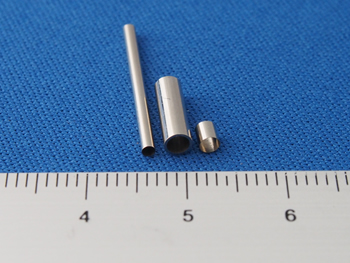

Micropipe

Advantages

- No-burr cut technology

- Up to 5um inner Au plating

- Crack resistive design by hardness adjustment

- Expanding inner diameter by thinning pipe-wall

Problems

It is very difficult to manage the gap control by using pipes made by standard methods.

Since standard pipes have thick wall, OD becomes larger when ID is prioritized, or ID becomes smaller when OD is prioritized.

OD outer diameter

ID inner diameter

Solutions

The normal ID tolerance of micropipe is ±0.003mm. Therefore, you don’t need to wait for ordering other parts until you actually inspect delivered pipes.

Micropipe’s wall thickness is easily adjustable.

You can expand ID with keeping the same OD or you can minimize OD with keeping the same ID.

Applications

- Spring probes

- Various nozzles

- Optical communication connectors

Resin Tube Tip Forming Die

Advantages

- Taper shapes

- R chamfering

- C chamfering

- ID φ0.5mm~

Problems

There is a big variation among the machined dies. Also, the inner surface is too rough to avoid the post-polish when they are delivered.

Solutions

Multiple identical copies are available from a single mandrel.

Inner surface is as smooth as Ra 0.1 or better so you don’t need additional polish.

Applications

- Catheter tip forming dies

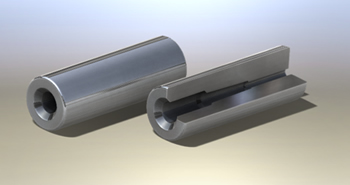

Thin-Wall & Thick-Wall Pipes

Advantages

- Any combinations of OD, ID, and length

- R chamfering

- C chamfering

- Slit cut

Problems

Better precision than machining is needed.

Pipes with thinner wall, higher aspect ratio, and stronger durability are needed.

Solutions

Wall thickness control is much easier by electroforming than machining.

High aspect ratio design became available with micropipe.

Durability of thin wall pipe increased by hardness control.

Applications

- Motor shafts

- Industrial endoscopes